NASA

"…outstanding service and value by doing work right the first time…."

"… record of customer satisfaction is second to none."

Assistant Branch Chief

NASA-Ames Research Center

ArcSine Engineering has performed many projects at NASA-Ames Research Center in Mountain View, California, and Johnson Space Center in Houston, Texas. Our work includes electric power, motor control, and instrumentation and controls. Following are brief project descriptions:

Wind Tunnels

For wind tunnels, ArcSine has performed fieldwork, analysis, and design on power distribution systems and programmable and hardwired control and safety systems.

Selected examples follow:

» 40 x 80- and 80 x 120-Foot Wind Tunnels

- Field evaluation and design of modifications to model support for 40 x 80-foot wind tunnel.

- Detailed design of model support for 80 x 120-foot wind tunnel.

- Analysis and report of drive system sequencing and controls for 40 X 80-foot wind tunnel.

- Analysis and testing of fan motor fields for the 40 x 80-foot wind tunnel.

- Preparation and execution of sequence test procedures for safety logic protecting IFC’s and fan-drive motors.

- Analysis, design, installation, and startup assistance of reduced-voltage start system for the A1 machine of the IFC (Induction Frequency Changer).

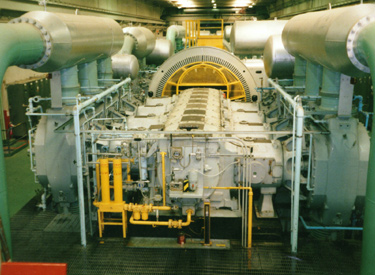

» Unitary Plan Wind Tunnel

- Complete design of the hardwired safety system for the main drive (180,000 hp) and auxiliary equipment during facility rehabilitation.

- Assistance with Unitary auxiliary system modification, including inspection during removal and reinstallation of the Unitary drive motors (four at 45,000 hp) for rewinding.

- Troubleshooting of wiring problems associated with interfacing new and existing equipment. Preparation and execution of safety test procedures and safety review of design modifications to the hardwired safety system.

» 14-Foot Wind Tunnel

- Assisted Code DQ with investigation of 6.9-kV circuit breaker mishap at the 14-foot wind tunnel.

- Design, installation, and startup of replacement dc loop contactor and loop cabling rated 1,000 volts, 2,000 amps.

- Power distribution for laser system.

» 12-Foot Pressurized Wind Tunnel

- Trouble calls and design modifications for laser seeder project.

» 7 x 10-Foot Wind Tunnel

- Design and startup of control system, including programmable logic controller system, for 3,000-psi air system.

Flight Simulators

Design, construction management, and assistance with startup and acceptance testing for two major simulator projects: Six-Degrees-of-Freedom Flight Simulator (S.01 Simulator) and Vertical Motion Simulator (VMS). Scope included drive and building power, dc drives, ac drives, hydraulic drives, failsafe hardwired safety systems, and feedback control system.

Design, construction management, startup, and testing for rehabilitation of flight and guidance centrifuge. Investigative study of replacement drive systems and replacement digital control systems for facility-wide upgrades. Developed a facility master plan, including a facility-wide electrical/electronic evaluation, recommendations, and design of upgrades. Continuing maintenance and troubleshooting on VMS resulting in the design and replacement of the obsolete annunciator with a sequence-of-events recorder and the obsolete Mode Control Unit with a high-speed programmable digital system.

Arc Jet Facilities

- Review, design, and testing of modifications to power transmission system for 60-Megawatt DC Power Supply.

- Preparation of maintenance plans, including surveys, evaluations, and analysis of 20- and 60-Megawatt DC Power Supply.

- Design, construction management, and startup of 20-Megawatt DC Power Supply rehabilitation, 60-Megawatt DC Power Supply digital control system, 60-Megawatt DC Power Supply data acquisition system, and portions of the control system for the Direct-Connect Arc Jet Facility, including programming and testing of the programmable logic controller system.

- Design, construction support, startup of improvements to the Johnson Space Center (Houston, Texas) Arc Jet power supplies.

- Failure investigations and reports for the Interaction Heating Facility.

Power Distribution

Analysis of base-wide power distribution to determine the cause of high-peak currents to 60-Megawatt DC Power Supply. Wrote high-voltage switching course. Performed relay coordination study and designed 50-MVA substation addition to the 115,000-volt system.

Other Projects

Provided studies, analysis, and design engineering services for several projects including the Building N238 DI Water Pumping Station (2,000-hp), Building N230 rehabilitation, Building N238 rehabilitation, 20G centrifuge control rehabilitation, and other facilities.